|

Premium Bridge PlugDownload document |

|

Advantages:

|

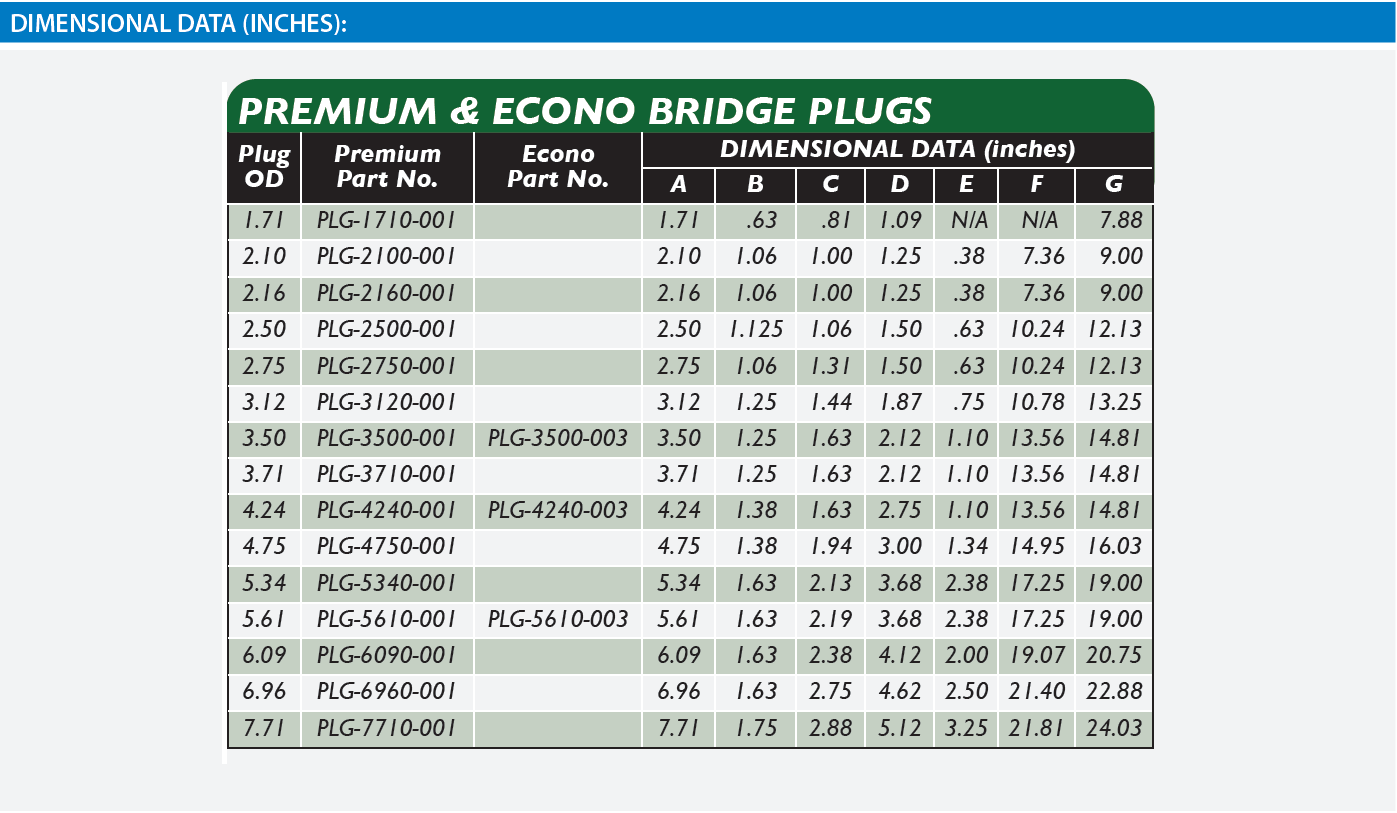

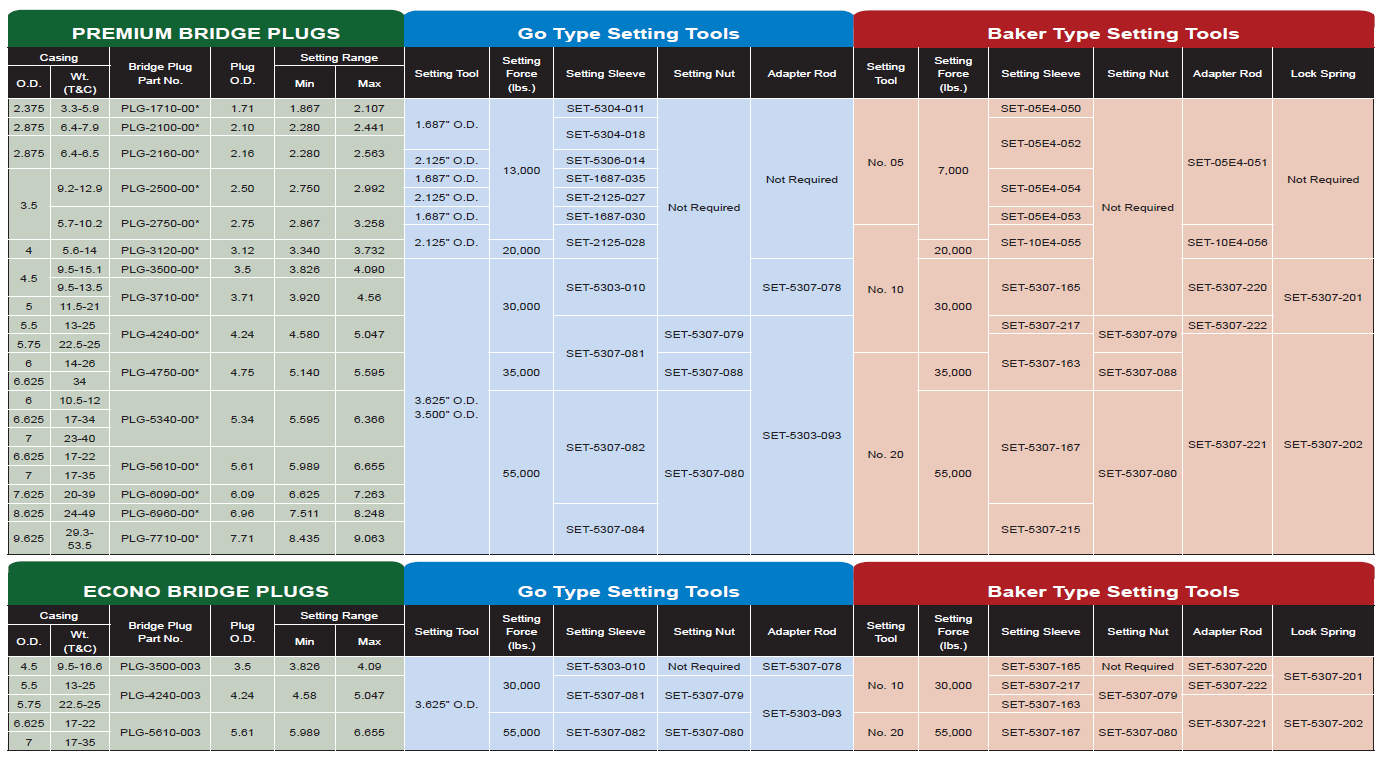

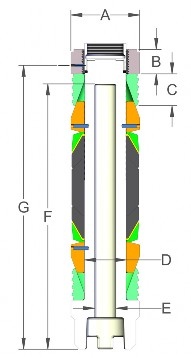

SPECIFICATIONS

|

SUGGESTED ROTARY DRILLING TECHNIQUE FOR OWEN BRIDGE PLUGS: The following is a general guide for the most successful drill-out technique

One or more junk baskets should be used above the bit when normal circulation is employed. |